Return

Print

Email

PFERD Carbide Bur Set 3 Piece MICRO Cut 1/8" Shank Plastic Case

Call For Price

- Part Number: 21827550

- UPC: 04007220424353

- Availability:

Quantity:

Add To Quote

Add To Estimate

Add To Wishlist

Compare Item

Product Overview

Info & Guides

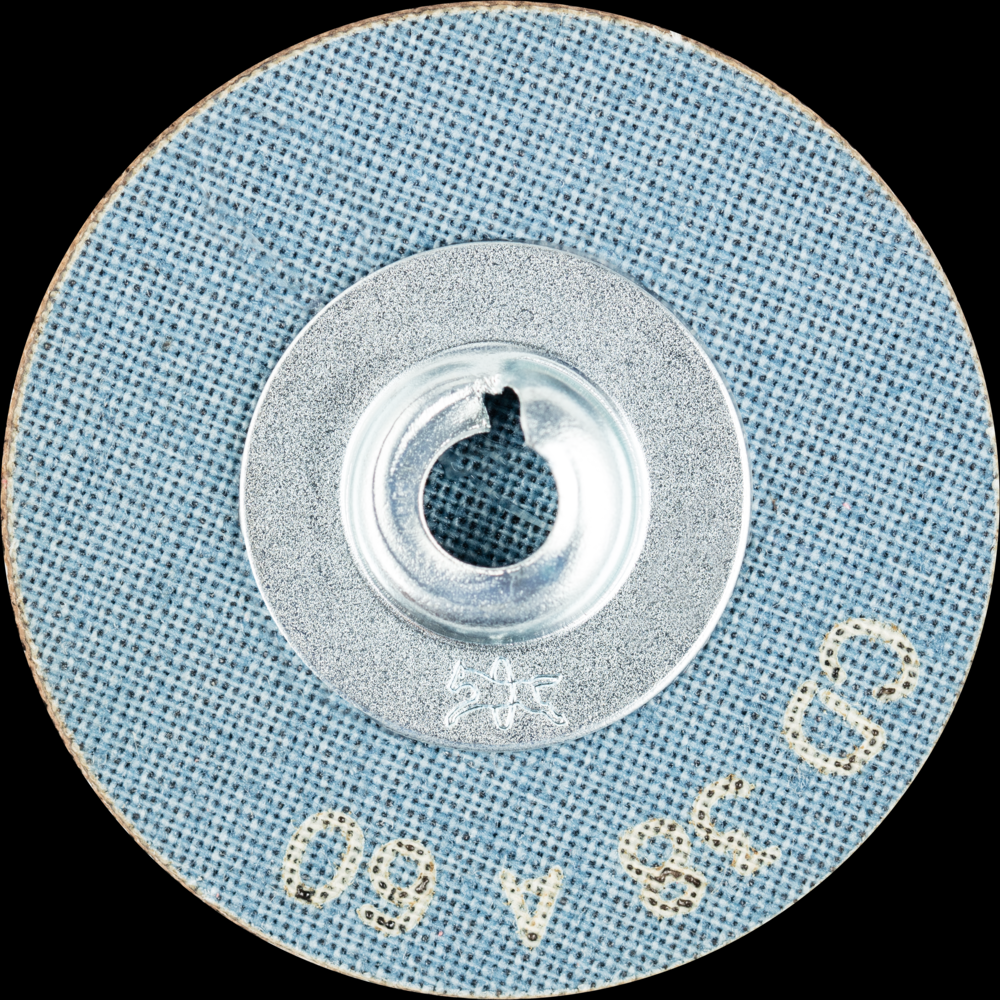

MICRO cut tungsten carbide burs are specifically designed for finishing and are used in areas where mounted points are often used. They offer a higher stock removal rate and produce a high surface quality, particularly when compared to conventional double cut burs. MICRO cut burs also operate with low vibration and little noise, they maintain their geometry over their entire service life, and they work in both manual and machine applications. MICRO cut burs can machine almost all materials up to a hardness of 940 HV (68 HRC). This set contains three small tungsten carbide burs for finishing work in the most common shapes and dimensions. The sturdy plastic box protects the burs against dirt and damage.

Specifications

Details

Industrial Category:

Machining

Industrial Subcategory:

Finishing Supplies

Industrial Subtype:

Carbide Bur Sets

Applications:

Cutting out holes

Applications 1:

Deburring

Applications 2:

Leveling

Applications 3:

Milling

Applications 4:

Milling out

Applications 5:

Surface work

Applications 6:

Work on weld seams

Country of Origin:

DE

Cut:

0

Drive Types:

Manual application

EAN:

4007220424353

EDP:

27550

Item Quantity:

1

Item Weight (kgs):

0.473

MANUFACTURER_TYPE_DESCR:

SET 3-TLG MICRO CUT

Materials that can be worked:

Annealed cast iron

Materials that can be worked 1:

Black annealed cast iron (GTS, GJMB)

Materials that can be worked 10:

Nickel-based alloys (e.g. Inconell and Hastelloy)

Materials that can be worked 11:

Stainless steel (INOX)

Materials that can be worked 12:

Steel

Materials that can be worked 13:

Steel, cast steel

Materials that can be worked 14:

Steels up to 370 HV (< 38 HRC)

Materials that can be worked 15:

Steels over 220 HV (> 95 HB)

Materials that can be worked 16:

Steels up to 220 HV (< 95 HB)

Materials that can be worked 17:

Titanium

Materials that can be worked 18:

Titanium alloys

Materials that can be worked 19:

Tool steels

Materials that can be worked 2:

Bronze

Materials that can be worked 20:

White annealed cast iron (GTW, GJMW)

Materials that can be worked 3:

Case-hardened steels

Materials that can be worked 4:

Cast iron

Materials that can be worked 5:

Cast steel

Materials that can be worked 6:

Cobalt-based alloys

Materials that can be worked 7:

Grey/nodular cast iron (GG/GJL, GGG/GJS)

Materials that can be worked 8:

Hard non-ferrous metal

Materials that can be worked 9:

Hardened, heat-treated steels over 370 HV (38 HRC)

Prop 65:

View

Recommendations for use:

Ideal for finishing, very fine cleaning work, corrections in tool and mold construction, and for sharpening cutting tools.

Recommendations for use 1:

Use the burs on powerful power tools with elastically mounted spindles to avoid unwanted vibration.

Recommendations for use 2:

Observe the recommended rotational speed.

Shape:

Three square

UNSPNC:

23251706

UPC Code:

97758275507

Other Details

High surface quality.

The highly accurate concentricity enables precise work free from chatter marks. This considerably reduces wear on the bur and power tool or machine.

Unlike with abrasive mounted points, there is no change in geometry due to wear and tear.

Work on almost all materials up to 940 HV (68 HRC).

Shipping charges TBD…You will be contacted to confirm your order and credit card information.

Thank you for your business.

Contact CCS for volume discounts on your order.

Freight charges from Canada will apply

Thank you for your business.

Contact CCS for volume discounts on your order.

Freight charges from Canada will apply