Return

Print

Email

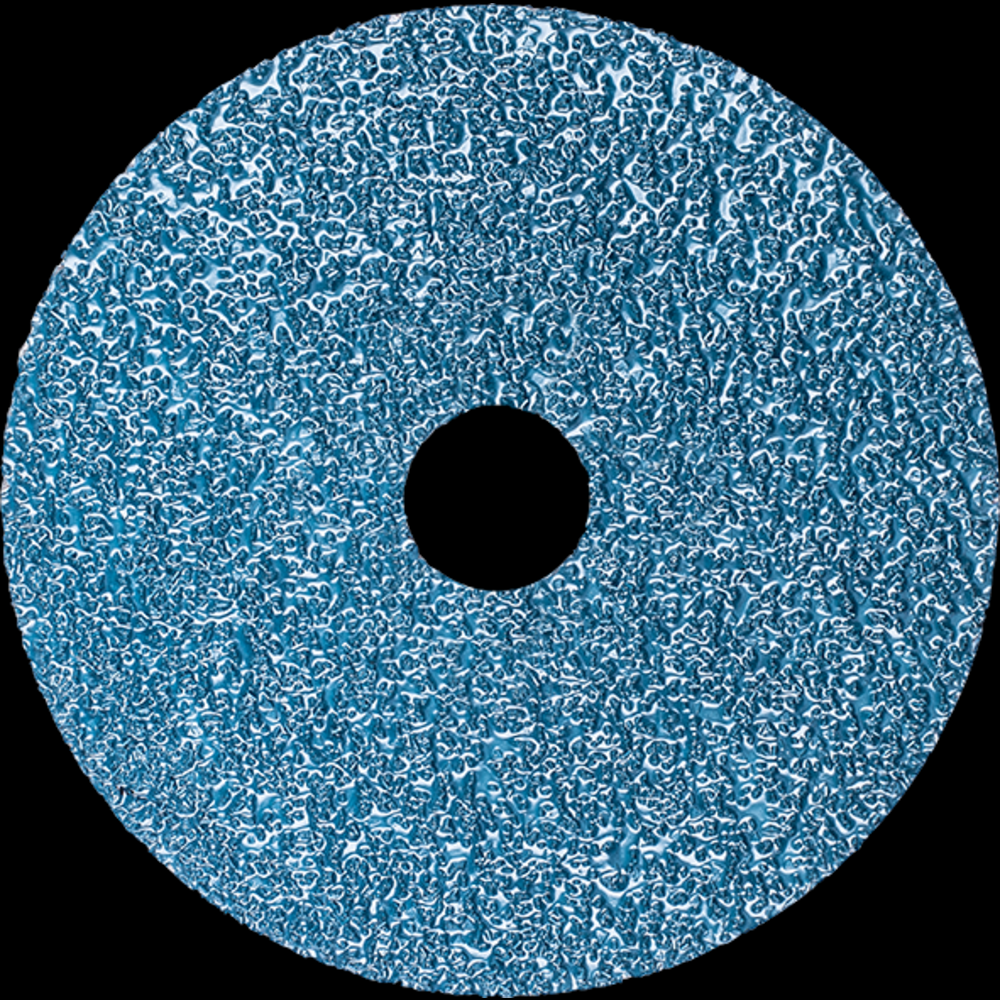

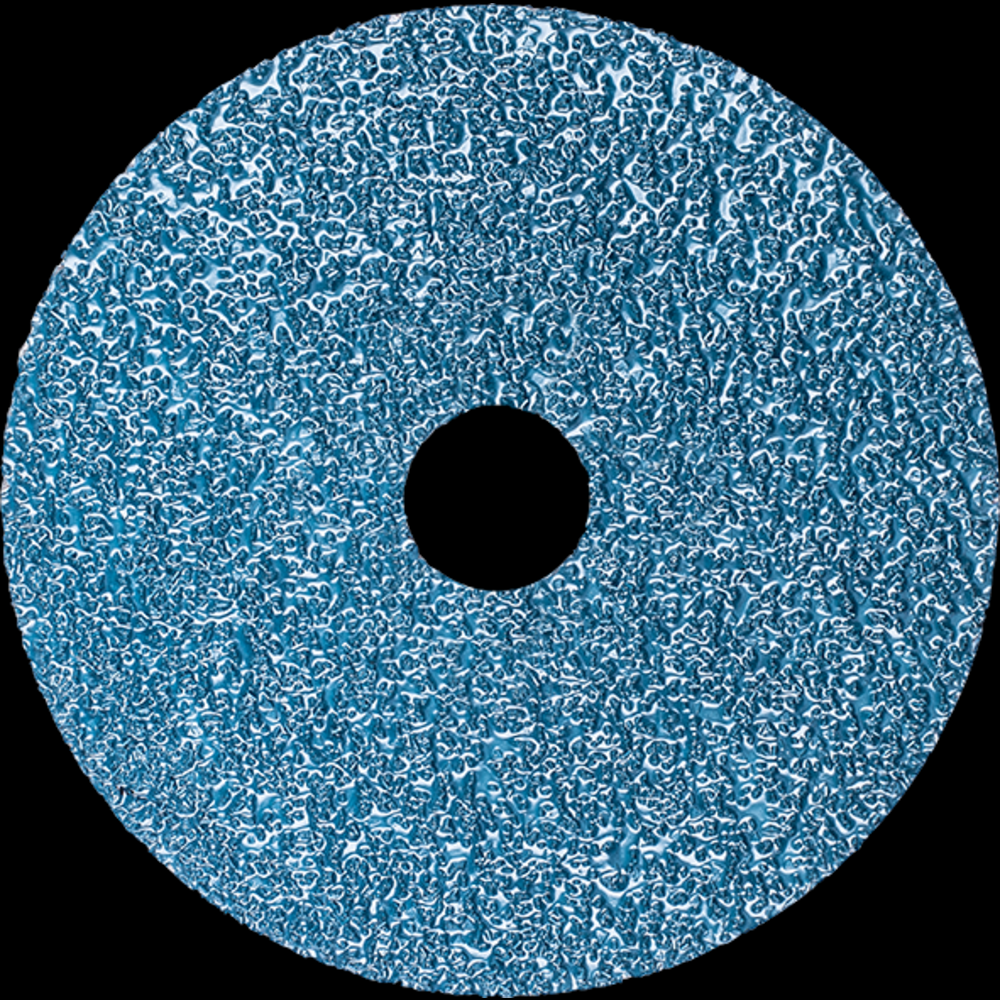

PFERD Fiber Disc, 5" x 7/8, 36 grit, VICTOGRAIN®

Call For Price

- Part Number: 64279016

- UPC: 04007220217160

- Availability:

Quantity:

Add To Quote

Add To Estimate

Add To Wishlist

Compare Item

Product Overview

Info & Guides

PFERD fibre discs are manufactured in accordance with ISO 16057 in shape A2 version F under the designation "vulcanized fibre disc". For maximum aggressive grinding with an extremely long tool life and an outstanding stock removal rate on steel and hard materials. Outstanding, constant high performance due to the VICTOGRAIN abrasive grain. Each VICTOGRAIN abrasive grain triangle is firmly fixed on one of its sides to the backing material. Due to the slim design, VICTOGRAIN offers an extremely large chip space for maximum cutting efficiency. The structure of the triangular VICTOGRAIN is specially engineered to maximize results. The very fine crystalline structure ensures optimal wear characteristics as sharp cutting edges are always exposed, with the minimum amount of abrasive breaking off from the triangle. By combining all these properties together, users benefit from optimal, consistent performance, cool grinding and an extremely long service life with uniform workpiece surface roughness.

Specifications

Details

Industrial Category:

Abrasives

Industrial Subcategory:

Abrasive Wheels, Discs and Brushes

Industrial Subtype:

Sanding Discs and Kits

Category Level 4:

Fiber Discs

Abrasive:

VICTOGRAIN

Country of Origin:

DE

Customs Number:

6805301000

Diameter External (In):

5

Diameter Hole:

7/8 Inch

EAN:

4007220217160

EDP:

40337

Grit Size:

36

Item Quantity:

25

Item Weight (kgs):

0.035

Prop 65:

View

Recommendations for use:

Use fibre disc in accordance with ISO 15636 with backing pad on commercially available angle grinders.

Recommendations for use 1:

Use the appropriate grinding oil for the material to significantly increase the service life and the abrasive performance of the discs.

Rpm, Max.:

12200

Safety notes:

The maximum permitted peripheral speed is 15,800 SFPM.

Safety notes 1:

For safety reasons, the maximum permitted rotational speed indicated must never be exceeded.

UNSPNC:

31191506

UPC Code:

97758403375

Other Details

Conforms to contours due to high flexibility.

Consistent surface finish resulting from high-quality abrasives.

High productivity due to long service life and very high stock removal rate.

VICTOGRAIN abrasive grain allows for high productivity due to long service life, very high stock removal rate, less heat build-up in the workpiece, and a lower power output required for the power tool.

Shipping charges TBD…You will be contacted to confirm your order and credit card information.

Thank you for your business.

Contact CCS for volume discounts on your order.

Freight charges from Canada will apply

Thank you for your business.

Contact CCS for volume discounts on your order.

Freight charges from Canada will apply